Our strength

We make proposals on materials and flooring which require quality

and function to meet the hygiene management standard.

8

features to meet the qualification.

Odorless

No solvent order that allow us executing the work while the area is in operation.

Adhesion

Strong adhesion works not only keeping from peeling off but also from contamination.

Water/chemical resistance

Superior water/chemical resistance will keep from corrosion by acid and alkali.

Short processing period

Our aqueous materials with fast hardening enables short processing period.

Heat resistance

High heat resistance (maximum 120℃) will prevent from corrosion by high temperature water and steam.

Anti-slipping

Anti-slipping which lasts long will work for fall prevention.

Anti-friction/shock resistance

Superior anti-friction and shock resistance enable the passage of heavy items/vehicles.

Underlying moisture

With less adhesion failure by underlying moisture of the concrete, it works the best for renovation.

Our renovation works

① Enclosurecuring

1 hour

② Surface preparation(Machine cutting)

2 hours

③ Finishing(Mortar flooring)

2 hours

④ Completion

10 hours(Hardening time)

The worked area can be used after 15 hours from the start of

processing.

(It varies depending on the size of area.)

Processing Flow

① Meeting

② Proposing construction method

③ Schedule planning

④ Construction

⑤ Inspection

⑥ Work after inspection

Food factory/kitchen

Floors where high temperature water flows and experience frequent and drastic temperature change can be troubled with expanding, peeling and cracking by the heat shock. Our floor coating with strong water/chemical/heat resistance will prevent these troubles.

before

after

before

after

before

after

Flooring materials

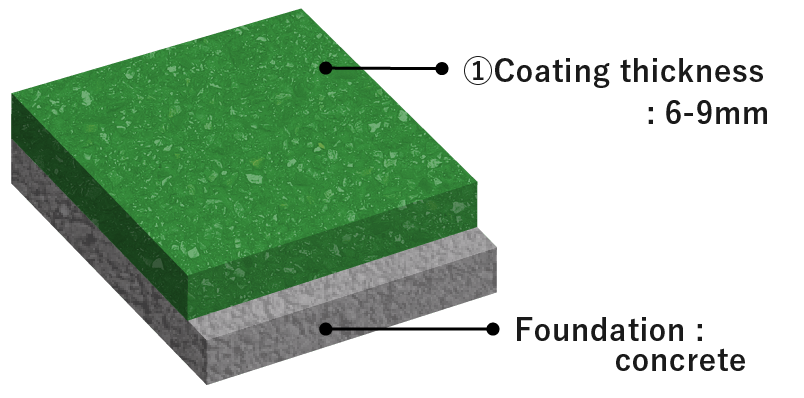

Mortar flooring

Aqueous rigid urethane resin flooring

Use

- Heating processing area

- Package handling area

- Area with high temperature water flowing

- Area where requires anti-slip coating

- Area where forklifts run

Cross section view

- Best suits to the area in food processing facility requiring durability.

- Heat resistance range: 80-120℃

- Anti-slipping: can retain anti-slipping quality at certain level.

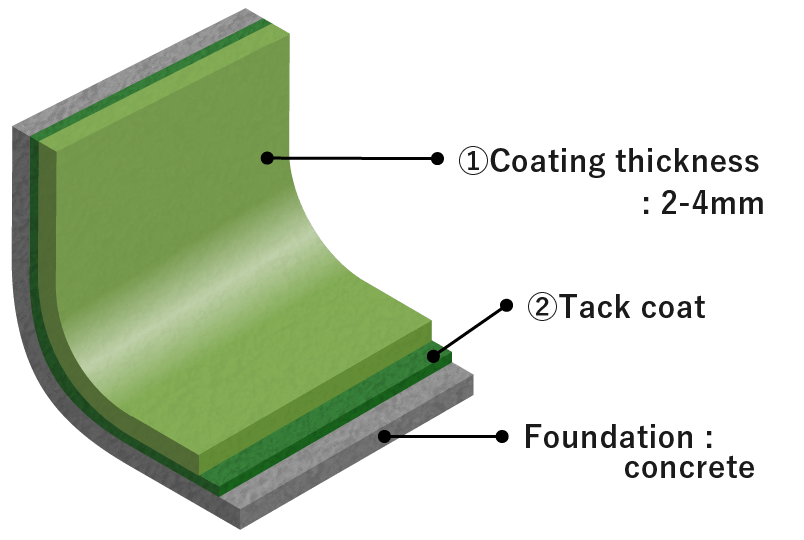

Mortar flooring

Aqueous rigid urethane resin flooring

Use

- Common in respective areas

- Drain port/basin rising face

- Skirting board (rising face)

- Internal corner R processing (50R)

Cross section view

- Best suits to the area in food processing facility requiring hygiene maintenance.

- The coating works well for contamination as it retains coating thickness of rising face and prevents peeling off. It also maintains hygiene by cleanability development with easy internal corner R processing (50R).